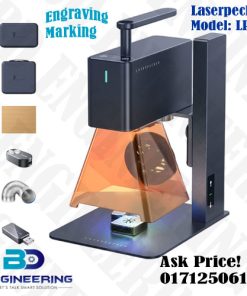

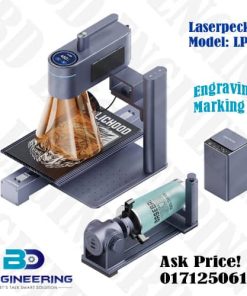

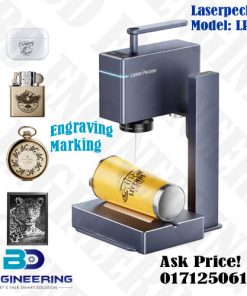

Laser Engraving Marking Machine

A 20-watt laser marking machine is a versatile tool capable of marking various materials using laser technology. The specific types of materials that can be marked depend on the type of laser source used (UV, CO2, fiber, etc.).

Machine can typically handle:

-

UV Laser Marking:

-

- Materials: UV lasers are effective for marking materials that are highly sensitive to heat, such as plastics, glass, and certain metals.

- Applications: Commonly used for marking and engraving electronic components, medical devices, and plastics.

-

-

CO2 Laser Marking:

-

- Materials: CO2 lasers are versatile and can mark a wide range of materials, including paper, cardboard, wood, glass, acrylic, leather, and certain plastics.

- Applications: Used in industries like packaging, woodworking, signage, and leather goods for engraving, cutting, and marking.

-

-

Metal Marking (Fiber Laser):

-

- Materials: Fiber lasers are specifically designed for marking metals and certain plastics.

- Applications: Ideal for marking stainless steel, aluminum, titanium, brass, copper, and engineered plastics commonly used in automotive, aerospace, and manufacturing industries.

-

-

Plastic Marking Laser:

-

- Materials: Laser marking on plastics can be done using UV, CO2, or fiber lasers depending on the type of plastic and desired marking quality.

- Applications: Used extensively for product branding, serial numbering, and traceability in the automotive, electronics, and consumer goods industries.

-

-

Other Features:

-

- Precision and Speed: Laser marking machines offer high precision and speed compared to traditional marking methods.

- Non-contact Process: Laser marking is a non-contact process, minimizing material damage and allowing for intricate designs.

- Automation Compatibility: These machines can often be integrated into automated production lines for efficient marking and engraving.

Summery:

When considering a 20-watt laser marking machine. It’s important to understand the specific requirements of your application. Such as material type, marking depth, speed, and resolution. Each laser type (UV, CO2, fiber) has its advantages and is suited for different materials and applications. Additionally, ensure that safety measures are in place, as laser systems can pose risks if not used properly.