What is redundant & redundancy in Automation Engineering method

In Automation engineering, redundancy refers to the including of extra components or devices with a system that are not strictly necessary for functionality. But serve as a backup in case of failure the control systems. This practice is the reliability, safety, and availability by ensuring that a system can continue to operate and functional even if part of its failures.

Types of Automation Redundancy:

- Component or devices Redundancy: Adding extra individual components like plc and power supply with control devices

- System Control Redundancy: Including complete backup systems like dual servers or duplicate data centers stations

- Functional Redundancy systems: Designing systems to have multiple ways of performing the same function as like different routes in the network

- Information Redundancy: Storing extra information to detect and correct errors like to parity bits in data storage to media.

Redundancy in Automation Engineering:

There have Redundancy in automation engineering refers to the inclusion of backup components or systems within a process to ensure uninterrupted operation even in case of failures or malfunctions operation. It’s a critical concept for building robust and reliable automation systems.

Benefits of Redundancy:

- Save Cost: Implementing redundancy increases costs.

- Complexity & easy solution: More components can lead to increased complexity and potential points of failure.

- Easy Maintenance: More systems require more maintenance and monitoring.

- Redundancy is a fundamental: The concept in engineering design, balancing reliability and cost to meet the desired performance and safety standards.

- Increased Uptime: Redundancy significantly reduces downtime by minimizing the impact of component failures.

- Enhanced Reliability: Critical systems with redundancy are more likely to operate continuously without interruptions.

- Improved Safety: In safety-critical applications, redundancy can prevent catastrophic failures and ensure the safety of personnel and equipment.

- Data Integrity redundant & redundancy in Automation Engineering method is a very easy operation

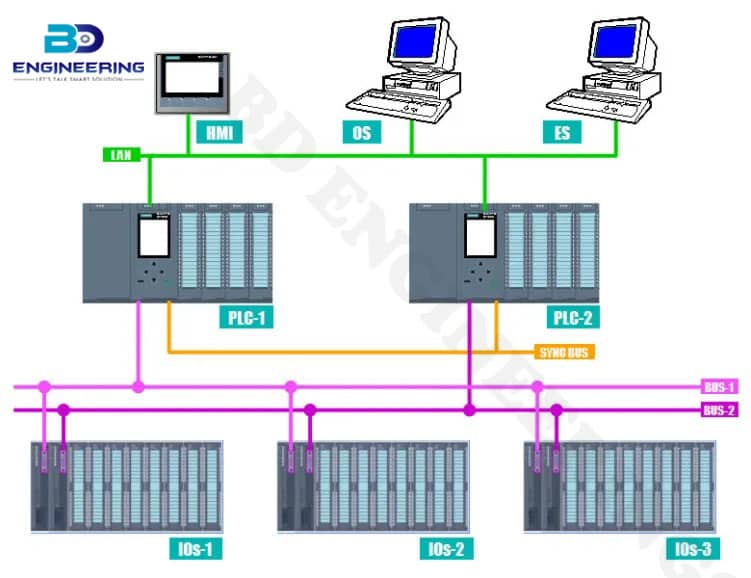

Practical Example of redundant PLCs:

- In the manufacturing plant, having redundant PLCs and I/O modules, and network switches can be ensured that is production line keeps running even if one component fails. This prevents costly downtime and production losses.

- By carefully considering the critical components and software development of an automation system and implementing appropriate redundancy measures, it’s possible to achieve high levels of system.

Hardware Redundancy:

- Dual Controllers Devices: Employing two identical controllers for critical tasks, with one acting as a hot standby while the other is active.

- Redundant I/O Modules: Using to multiple I/O modules for critical inputs and outputs to ensure data integrity and system operation even if one module fails.

- Power Supply Redundancy: Having dual power supplies or uninterruptible power supplies (UPS) to maintain system operation during power outages or fluctuations.

Functional Redundancy area

- Diversity: Using different technologies or components for the same function to reduce the likelihood of simultaneous failures. For example, using both pneumatic and hydraulic systems for a braking mechanism.

- Voting Systems: Employing multiple sensors or actuators to provide redundant data or control signals. The system makes decisions based on a majority vote among these components.

Challenges and Considerations

- Cost: Redundancy can increase initial investment due to additional hardware and software requirements.

- Complexity: Implementing and maintaining redundant systems requires careful planning and expertise.

- False Positives: Redundancy systems might trigger false alarms, requiring proper configuration and testing to minimize false positives.

- Performance Impact: In some cases, redundancy can introduce slight performance overhead due to the need for communication and synchronization between redundant components.

Case Studies and Examples:

- Automotive Power Plant: Redundant PLCs and I/O modules to ensure continuous power plant in case of component failures. Mostly important of continues production line of manufacturing

- Process Control systems: The Redundant sensors, actuators, and controllers to maintain critical process parameters and prevent safety hazard issues.

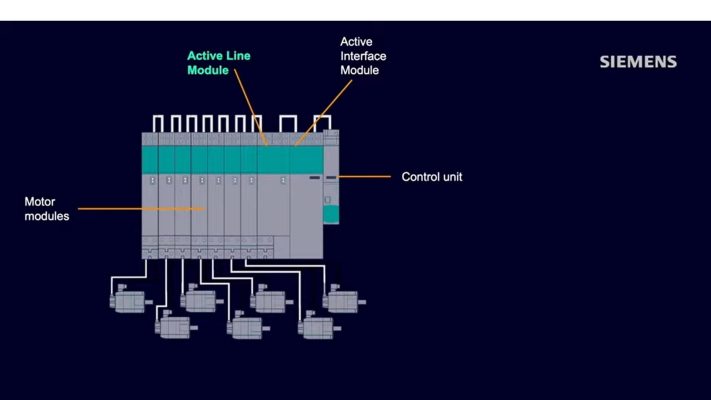

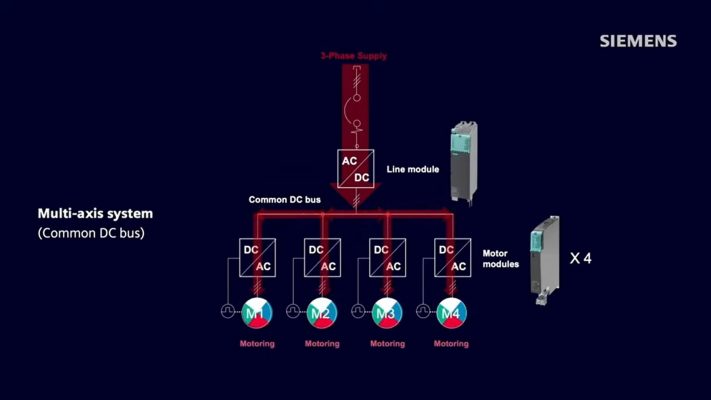

- Inverter-VFD redundant Systems: Most of company make sure of redundant functionalities VFD_Inverter for various application

Practical Implementation of Redundancy:

I/O Redundant

- Dual I/O Modules: Employing two identical I/O modules for critical inputs and outputs. Data from both modules is compared, and discrepancies are flagged or corrected.

- Remote I/O: Distributing I/O modules across multiple locations to reduce the impact of a single point of failure.

Network Redundancy:

- Ring Topology: Creating a closed-loop network where data can be transmitted in both directions, improving fault tolerance.

- Redundant Switches: Using multiple switches to provide alternative communication paths.

- Industrial PC: Offering higher reliability application for both application continues runing that can use IPC systems control panel.

Power Supply Redundant:

- Dual Power Supplies: Employing two separate power supplies to ensure continuous operation even if one fails.

- Uninterruptible Power Supplies (UPS): Providing backup power during power outages.

Automotive Assembly Line:

- Redundant PLCs: Two identical PLCs control critical assembly processes, with one acting as a hot standby.

- Redundant I/O Modules: Critical sensors and actuators are connected to dual I/O modules to prevent production stops due to I/O failures.

- Redundant Network: A ring topology network with multiple switches ensures uninterrupted communication.

Oil and Gas Platform utilities area:

- Dual system Controllers: Two identical PLCs control safety-critical functions like emergency shutdown systems with utilities operation area.

- Redundant Sensors: Critical sensors like pressure and temperature sensors have multiple units for cross-checking input data systems.

- Uninterruptible Power Supplies (UPS): UPS systems provide backup power to critical equipment during power outages.

Challenges and Optimization controllers:

- Cost-Benefit Analysis: Evaluate the potential financial impact of system downtime versus the cost of implementing redundancy systems automation development

- Testing and Validation: Thoroughly test the redundant system to ensure proper operation and failover mechanisms.

- Complexity Management: Simplify the system design to avoid excessive complexity that can hinder troubleshooting and maintenance.

- Dynamic Reconfiguration: Explore options for automatically reconfiguring the system in case of failures to minimize downtime.

Standby redundancy in the PLCs concepts:

- Hot to Standby:

- Two PLCs are continuously online and synchronized.

- One PLC is active, while the other is in a standby mode continues, monitoring the primary for failures.

- Upon failure detection, the standby PLC takes over seamlessly, ensuring minimal downtime.

- Warm to Standby:

-

- Similar to hot standby, but the standby PLC might not be fully synchronized with the primary.

- It might require some time to synchronize or load programs after taking over, resulting in a slightly longer recovery time.

- This option is suitable for applications where short interruptions are tolerable.

- Cold to Standby:

-

- The standby PLC is completely offline until the primary fails.

- Manual intervention is required to bring the standby online, leading to longer recovery times.

- This option is suitable for non-critical systems where downtime can be planned.

Redundancy in I/O Systems of PLC controller

- Dual I/O Modules: Employing two identical I/O modules for critical inputs and outputs. Data from both modules is compared, and discrepancies are flagged or corrected.

- Remote I/O: Distributing I/O modules across multiple locations to reduce the impact of a single point of failure.

Network Redundancy topology:

- Ring-Topology: Creates a closed-loop network where data can be transmitted in both directions.

- Redundant Switches: Using multiple switches to provide alternative communication paths.

- Fiber Optic Cables area: Offers higher reliability and resistance to electromagnetic interference compared to copper cables.