In this Blog, we will learn about SCADA and Application of SCADA in Electrical Power Systems.

In the early times when electric power systems began developing, electricity generation shops were only associated with their respective Sector separate original loads. If anything failed in the whole linearly connected system, However, which could include subsystems like generating factory, power lines, connections, then the lights would be out. Customers did not accept that how to depend on electricity. Outages, whether routine or exigency, were taken as a matter of course. As reliance on electricity grew, so did the need to find ways to ameliorate trust ability.

SCADA and Application of SCADA in Electrical Power Systems

Generating stations and power lines were connected to give redundancy. As the system expanded and began to gauge out in size, it came harder to manage.

Results were demanded to face the challenges of controlling outfit over long distances. To overcome this, operating help were frequently posted at the important points in this grid system so that they could cover and snappily respond to any problems that might arise due to any fault or failure. They would communicate with central electricity dispatchers, frequently employing telephone, to keep them informed about the condition of the system.

Numerous manufacturing bottoms, remote spots, and artificial shops reckoned on help to cover outfit and manually control through mechanical drive buttons and analog dials. As the demand for dependable electricity grew indeed more and as labor came a significant part of the cost of furnishing electricity, technologies similar as SCADA were developed full program with problem solving documentation which allow remote monitoring and control of the system‘s crucial parameters.

What is SCADA

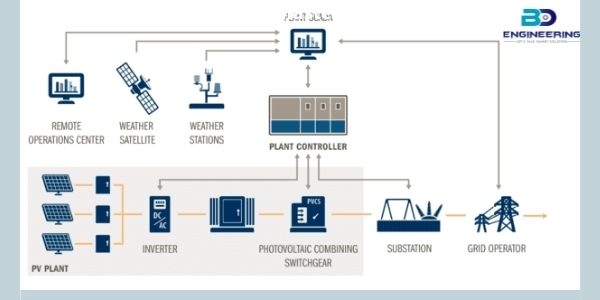

SCADA means Supervisory Control And Data Acquisition. SCADA is a system of different tackle and software rudiments that come together to enable a factory or installation driver to supervise and control processes.

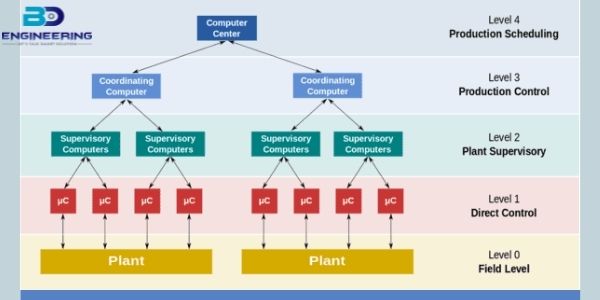

Administrative control is a general term for a high– position of overall control of numerous individual regulators or multiple control circles. It gives the operations administrator an overview of the factory process and permits integration of operation between low– position regulators.

Data accession is the process of slice signals by measuring a physical property of the real world in the form of signals and converting it from analog waveform into digital numeric values so that it can be reused by calculating machines.

The Main features of SCADA

Computers reuse the data and let help in charge to oversee and direct the captions of the power system using the required data. Facilities in charge frequently drivers and masterminds those who cover the information ever or locally. Now, the master station is master station is assigned to supervise utmost of the system. If you need SCADA service in Bangladesh

Control

Control in SCADA refers to providing command messages to a device to operate the Instrumentation and Controls system (I&C) and power system devices. On the other hand, SCADA relies on human managers to initiate command from an operator console on the master computer.

Data collection

Instead of collecting data and filling datasheets by hand, SCADA formally compiles information in fixed time. SCADA gain data from 100 or even thousands of sensors at a showing time. It also make backlogs for later requirement analysis.

Data communication

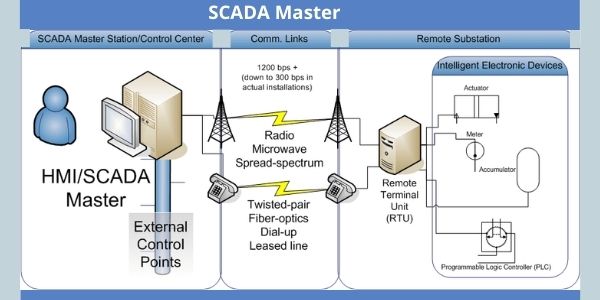

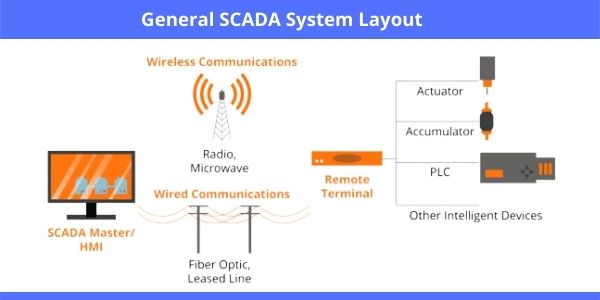

SCADA provides information to a central fix hub. A transport communication network transport all the data gained from sensors. First systems had radio or modem.

Data presentation

SCADA make connect with human operators into work station desktop that deploy the human machine interface, HMI. The master station presents a spread view of the full system and notice the operator by visual display or alarm sound. If want to learn SCADA and Its Application in Electrical Power Systems then contact with us.

Components and Functions of SCADA

SCADA system comprises of the following components

Sensors:

Field instruments are an array of transmitters, observers, and detectors. detectors. Detectors are the transducers which descry changes in physical volume. These detectors can be analog or digital, but eventually their purpose is same. Detectors help its druggies to measure and collect data from colorful locales. The more complex a system, further detectors we may need in place.

Conversion units:

Field instruments are an array of transmitters, observers, and detectors. Detectors are the transducers which descry changes in physical volume. These detectors can be analog or digital, but eventually their purpose is the same. Detectors help its druggies to measure and collect data from colorful locales. The more complex a system, the further detectors we may need in place. There are types of conversion units that worked in a SCADA system they are PLCs and RTUs.

Programmable logic controllers (PLCs)

Programmable sense regulators are good for situations where we want more localized control. The programmable sense regulator is an artificial digital computer designed for affair arrangements and multiple inputs. PLC is used occasionally in place of other conversion units due to their versatility, inflexibility, affordability, and configuration. Still, one may need good programming chops to make the most out of it.

Remote terminal units (RTU)

Remote terminal units are microprocessor- controlled electronic bias. Their ideal is to affiliate a SCADA system with a detector or whatever expostulate the RTU is connected to. Typically, they transmit information through wireless communication. Thus, they’re considered good for functions covering a broad area geographically.

The below conversion units help as original collection points for gathering information from detectors and delivering commands to control and protection relays.

Communication network:

SCADA system can not live without a duly designed communication network system. All the SCADA system aspects calculate solely on the communication network. It provides a channel for the inflow of data between the administrative control, the data accession units, and any regulator that’s connected to the system. The main function of communication network within a SCADA system is to connect the Conversion units with the SCADA master station. The data can be through colorful communication platforms similar as ethernet, telephone line, power line carrier communication, optic fiber line, cellular, radio, satellite, Wi-Fi, fryer, or other wireless protocol. Utmost installations have specialized intertwined network connectivity field motorcars, wired or wireless, due to security reasons.

Remote communication server (RCS):

After recycling and assaying the data gathered in the SCADA system, one needs a digitally and physically secure place to store this vast database. The mortal-computer interface (HCI) or HMI generally requests data from a garcon responsible for data accession, a element of tackle that’s used to connect software services to the conversion units out in the field. The garcon makes data accession from these original units possible.

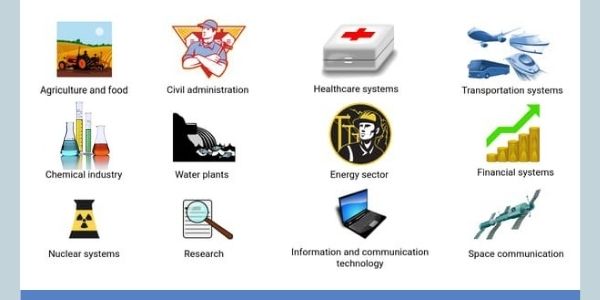

Applications of SCADA

Generally, We use SCADA systems when a need arises to automate complex processes where mortal control isn’t doable. Thus the SCADA perpetration of power system improves the overall effectiveness of the system for optimizing, supervising, and controlling the generation, transmission & distribution systems. SCADA function in the power system network offers lesser system trust ability and stability for integrated grid operation.

SCADA for power generating stations:

Bringing an optimal result for each process to involve in power generation is flexible with advanced control structures. With the use of PLCs and important machine communication links along with SCADA software and tackle in generating stations, it supervises several operations including protection, monitoring, and controlling. To give dependable energy, to minimize functional costs, and to save capital investment, the SCADA system is taken as seriously in generating stations.

The stressed functions of SCADA in power shops include:

-

-

- Nonstop monitoring of speed and frequency of electrical machines

- Electricity generation operations planning

- Control of active and reactive power

- Monitoring of renewable energy granges and cargo dispatch planning

- Cargo scheduling

- Literal data processing of all generation affiliated parameters

- Supervising the status of circuit combers, defensive relays, and other safety outfit

- Power outfit health examiner

- The sequence of events recording

-

SCADA for power transmission system:

Transmission line corresponding circuit model parameters are frequently in error as compared to values measured by the SCADA system. Without a SCADA system, these crimes beget the profitable dispatch to be incorrect, and hence, lead to increased costs or incorrect billing. These crimes could also affect state estimator analysis, contingency analysis, short circuit analysis, distance relaying, machine stability computations, and transmission planning in case of expansion. Thus, SCADA integration into the transmission system is significantly considered.

The functions of SCADA in electric transmission system are as follows:

-

-

- Re-routing services for station maintenance

- Service restoration

- Protective relay interface/interaction

- Voltage regulation management

- Load tap changer control

- Transformer management

- Real-time modeling

- Interface real-time single-line displays

- On-line operation and maintenance logs

-

SCADA for power distribution system:

There are different companies who depend on manual labor to perform the distribution tasks. Such as interrupting the power to loads, hourly key metrics checking, any type of fault diagnosis, etc. SCADA implementation helps to the power distribution by reducing the manual labor operation and also its cost. So that, they can get the facilitates smooth processes by reducing disruptions.

-

-

- Increasing the power by controlling a tolerable range of power factor

- Checking the peak power demand

- Quick response to customer service interruptions

- Feeder automation and Load Sectionalized

- Automated meter reading

- Circuit breaker control, lockout, and interlocking

-

Moreover, Different types of Data acquisition and monitoring can be done smoothly if power systems are upgraded to SCADA. Now a days, electrical systems are very much logical and well organized to monitor and control all of the involved operations. For this reason, it has become very popular because of technological advancements. So, we can say that SCADA system is very important for the power sector to minimize their systems as per the requirements of the technical changes.