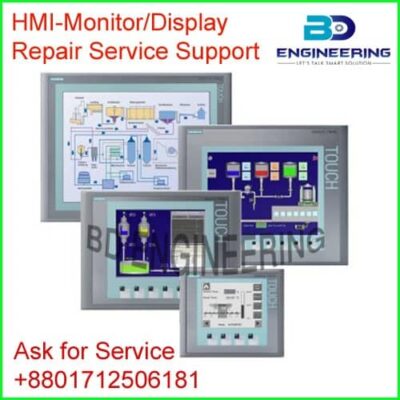

HMI (Human Machine Interface) Display for Machinery

A Human Machine Interface (HMI) is a user interface that allows interaction between humans and machines, particularly in the context of industrial automation and control systems. It provides a means for operators or users to monitor and control machines, processes, and equipment in a visual and intuitive manner.

Here are some key aspects and components of an HMI:

The primary purpose of an HMI is to facilitate the exchange of information between humans and machines, enabling operators to monitor system status, make adjustments, and receive feedback on the process being controlled. HMIs typically consist of hardware and software components that work together to provide a user-friendly interface.

Display/Screen HMI :

The HMI interface features a display screen that presents information and graphical representations of the system being controlled. It can include elements such as buttons, indicators, labels, graphs, and images to convey relevant data to the user.

Touchscreen or Input Devices:

HMIs often employ touchscreen technology to enable direct interaction with the displayed content. Alternatively, they may incorporate physical buttons, keypads, or other input devices to facilitate user inputs and commands.

Visualization and Control Software:

The software running on the HMI device processes data, communicates with the underlying control system or PLC, and renders the graphical interface. It provides tools for designing and configuring the HMI screens, defining alarms, trends, and other interactive elements.

Connectivity:

HMIs are typically connected to the control system or PLC through communication protocols such as Ethernet, Modbus, Profibus, or DeviceNet. HMI will be connected with PLC for machine operation control system

Alarms and Notifications:

HMIs can generate alarms or notifications to alert operators about abnormal conditions, faults, or critical events in the system. These alerts are usually displayed prominently on the screen and may include visual cues, audible alarms, or text messages.

Data Logging and Trending:

Many HMIs offer data logging capabilities to record process variables and events over time. They can also generate trend graphs or historical reports, allowing operators and engineers to analyze system performance and identify patterns or anomalies.

HMI’s play a crucial role in enhancing the efficiency, safety, and usability of industrial automation systems. They provide a visual representation of the process, allowing operators to monitor key parameters, adjust settings, and respond to changes in real time.